For high performance

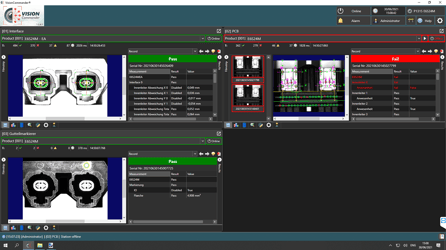

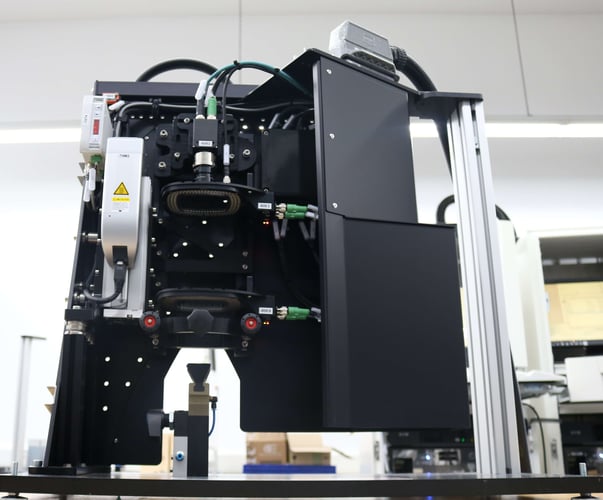

Quality Assurance in Connector ManufacturingWith our manual test station we can inspect connectors and connector assemblies as well as check the PCB and interface side at the same time.

Optical inspection for automated testing

We develop turnkey optical inspection devices for your manufacturing process

Our optical inspection devices ensure high quality in your industrial production

Tests during production using a testing device can identify weak points or quality defects in the product at an early stage. This saves time and money and ensures optimum product quality.

Plug & Play solutions for modern manufacturing environments

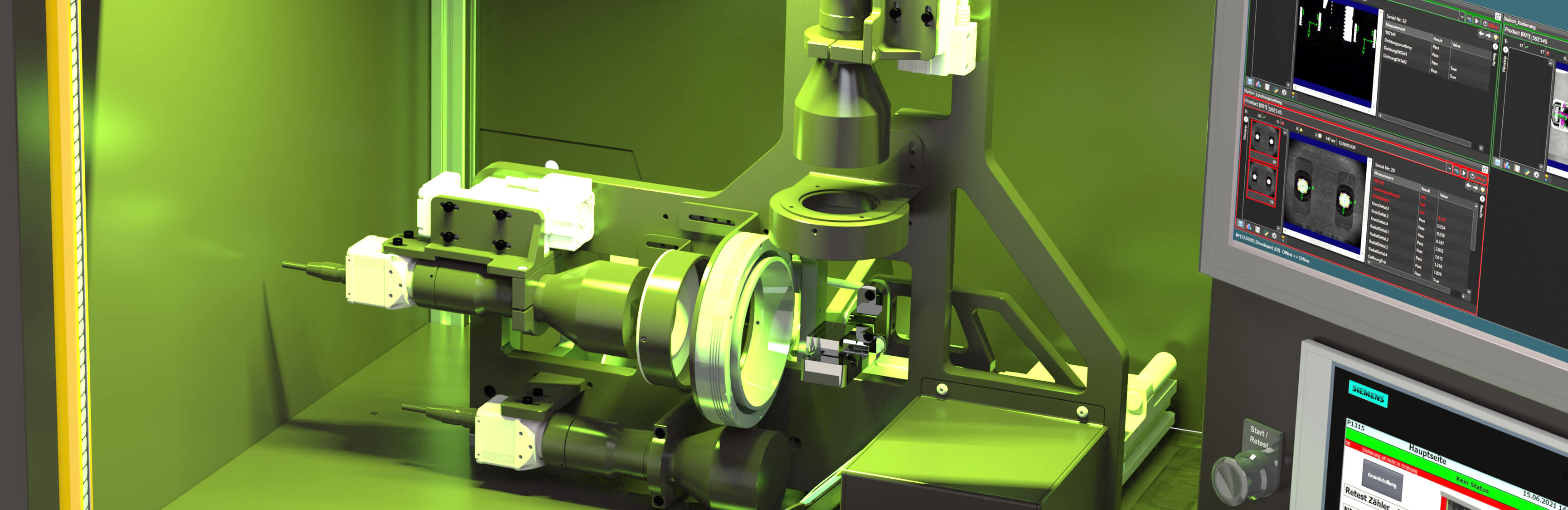

Manual test station for optical measuring and testing tasks

IO and NIO visualization via multicolor workstation lighting

Resolutions up to 50 megapixels / spatial resolution up to 1 µm

Marking good parts and rejects

Interchangeable part fixtures for testing different types of parts

Typical test time per part: 2 to 4 seconds

Siemens device control including Simatic HMI touch panel

Separate visualization of the measurement data on a full HD screen

Emergency off button

IO and NIO visualization via multicolor workstation lighting

Resolutions up to 50 megapixels / spatial resolution up to 1 µm

Marking good parts and rejects

Interchangeable part fixtures for testing different types of parts

Typical test time per part: 2 to 4 seconds

Siemens device control including Simatic HMI touch panel

Separate visualization of the measurement data on a full HD screen

Emergency off button

For high performance

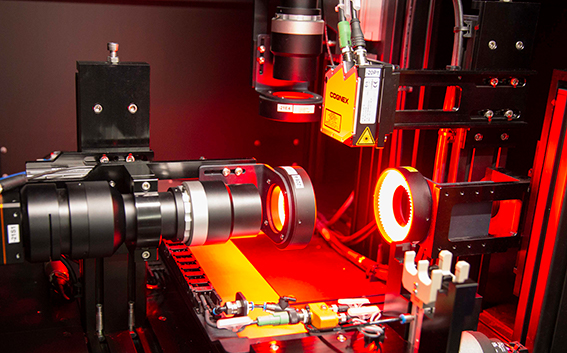

Quality Assurance in Connector ManufacturingWith our manual test station we can inspect connectors and connector assemblies as well as check the PCB and interface side at the same time.

Complex parts with complete processing

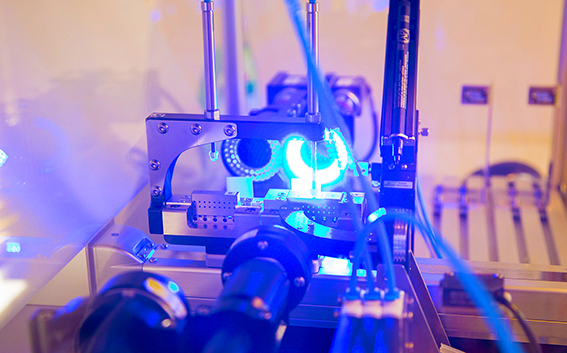

Quality Assurance in Polymers ProcessingThe VisionUnit workstation inspects polymer injection molded parts for dimensional accuracy, detects overmolding and undermolding, and detects deformations in injection molded parts.

Turnkey test unit for machine builders

Machine builders benefit from this during commissioning

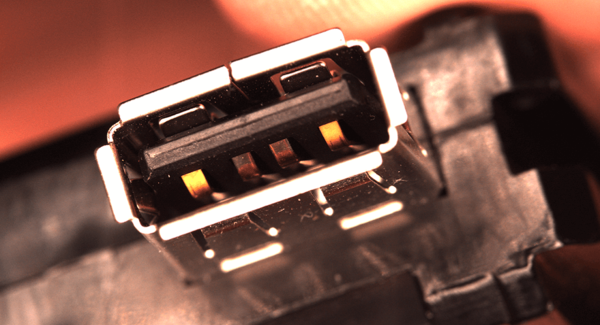

senswork's camera system precisely measures pin positions, connector coding and housing dimensions of MTD connector assemblies.

Capture products in high resolution using a barcode scanner and benefit from consistent image quality.

The VisionUnit from senswork enables precise inspection of USB connector contacts at different focal planes. Learn more!

Contact us!